Recently, it has become apparent that the manufacturing industry is embracing new technologies to enhance its product innovation capabilities. Tube laser has gained immense popularity among these advanced technologies, especially in producing PVD-coated furniture, known for its exceptional durability. Tube laser has now become an essential and trendy tool in the manufacturing industry.

Laser tube cutting is a highly efficient and precise process that utilizes advanced techniques to cut tubes, structural shapes, or channels with extreme accuracy. This cutting-edge technology ensures that these items are cut to the required length, with no room for errors or inaccuracies. Also, this technique offers a lot of benefits to the industry. Want to know what are those? You can gain sufficient knowledge if you stay to the end of this article as we will explain this topic in detail.

Various Benefits of Using the Tube Laser in the Fabrication Project

Have the Ability to Do More Than Just Straight Cuts

The three-dimensional rotating head of our machine can quickly and precisely cut through and around a tube’s radius. It is impossible to get the same results using conventional cutting tools.

Reduction in the Secondary Operation

Metal shavings and flaws in the cut edge are frequently left behind when cutting a tube with a physical blade. Due to these problems, the tube would need to undergo extra shaping and cleaning procedures to be ready for its intended use.

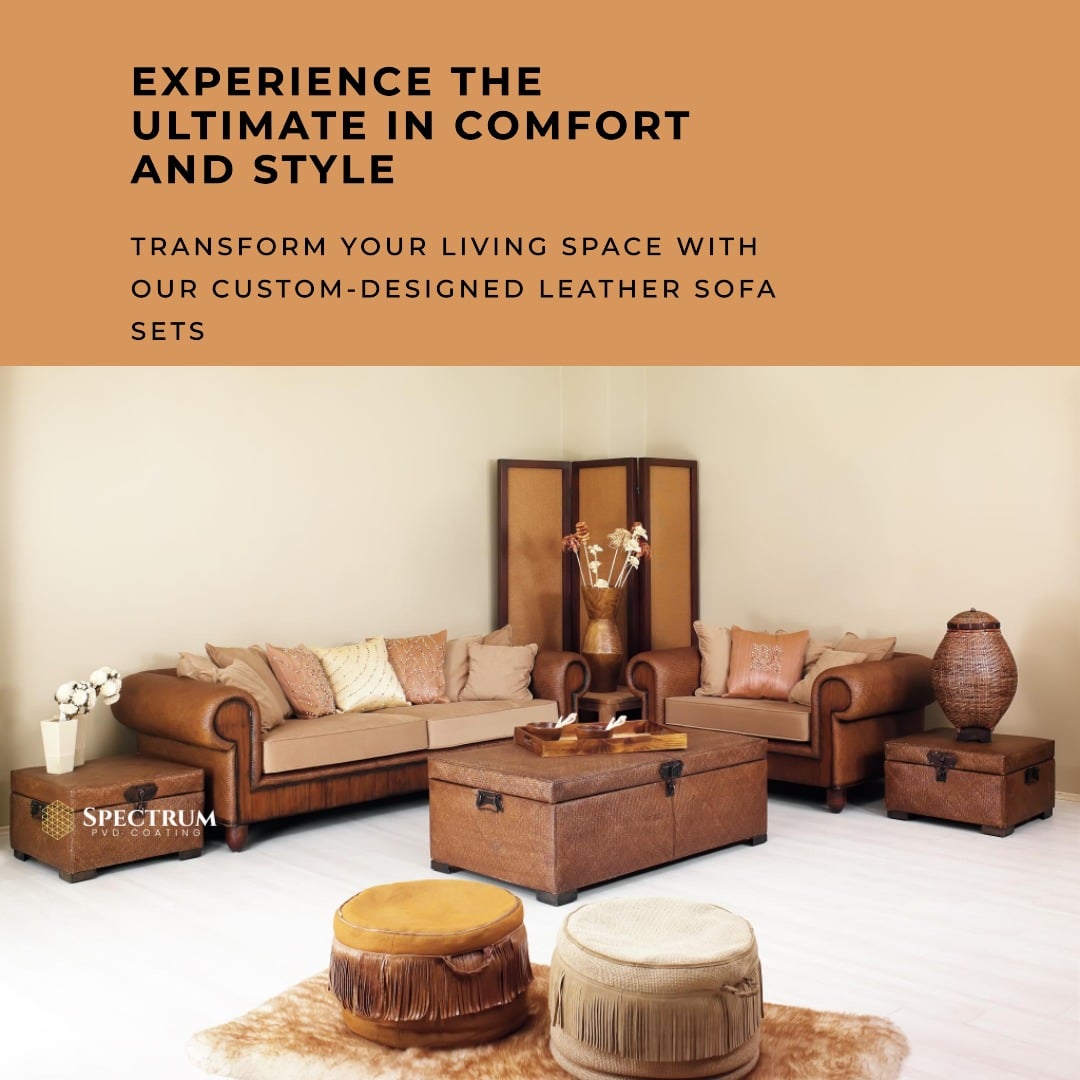

However, not only are the edges nearly flawless when utilizing a laser tube cutting machine with a splatter guard system, but the slag from the cutting process may be collected and kept out of the cut tube. As a result, these two procedures are no longer necessary. A tube-shaped object can be directly sliced with a tube-cutting machine. So, if you also want a luxury sofa set in Bangalore made with this process, contact your nearest manufacturer company.

Save a Lot of Saving

Utilizing tube laser cutting equipment offers companies several economic advantages. Cost reduction is one of the most significant benefits of using this kind of equipment. Firms can save time and money by eliminating unnecessary procedures or processes for metal fabrication projects. Because tube laser cutting machines can produce precise cuts with little waste material, they are the best option for decreasing costs in metal production operations.

High Precision Fabrication

Compared to traditional cutting techniques, tube laser cutting requires a considerably higher precision for intricate engineering designs. Higher levels of accuracy are possible using laser cutting equipment, which enables producers to create parts and components with precise tolerances. This makes it more likely that the final goods will satisfy the exact requirements of the final consumer and be of a consistently high caliber.

Energy Efficiency

A laser cutter utilizes less energy than conventional cutting techniques because of its efficiency and cutting-edge technology. Other cutting mechanisms use roughly 50kW of electricity during a cutting session, whereas laser cutters typically consume about 10kW. Laser cutters can aid manufacturers in their efforts to operate more efficiently and have less energy, which will benefit the environment and save money. Using laser cutters can significantly reduce the energy used in the fabrication process.

The above scenario shows why the manufacturing industry uses tube lasers to manufacture furniture.